Plant List

Advanced Manufacturing

CNC Milling

Accura has some of the most comprehensive milling capability in the West Midlands, with a wide range of systems. To meet our customers' needs, Accura have invested in the latest CNC milling capability including the DMG Mori DMU 100, DMU 60 and CMX 70U, as well as Mikron and Bridgeport machining centres and large milling machines.

| CNC milling | Quantity onsite | Max X-axis (mm) | Max Y-axis (mm) | Max Z-axis (mm) |

|---|---|---|---|---|

| 3 Axis CNC Milling Centres | 11 | 1200 | 600 | 675 |

| 3+2Axis CNC Milling Centres | 9 | 4000 | 1200 | 1500 |

| 5 Axis Milling Centres | 3 | 1000 | 1250 | 1000 |

Turning

Accura's turning capabilities include a state-of-the-art DMG MORI NLX2500/700 and an IEMCA BOSS 338-HD bar feeder for high volume production work. Combined with our CNC milling facilities, we are well equipped to handle complex turning projects.

| Turning | Quantity onsite | Max Length (mm) | Max Diameter (mm) |

|---|---|---|---|

| Mill / Turn Machining Centres | 1 | 1255 | 366 |

| Lathes | 4 | 1130 | 550 |

| Bar feed | 1 | 6000 | 38 |

Spark & Wire

With one of the largest wire EDM machines in the UK, Accura is able to handle the most complex parts. Our EDM systems are from industry-leading providers including Agie and Charmilles.

| Spark & Wire | Quantity onsite | Max X (mm) | Max Y (mm) | Max Z (mm) |

|---|---|---|---|---|

| Wire EDM | 4 | 800 | 550 | 525 |

| Die sinking EDM | 5 | 500 | 350 | 500 |

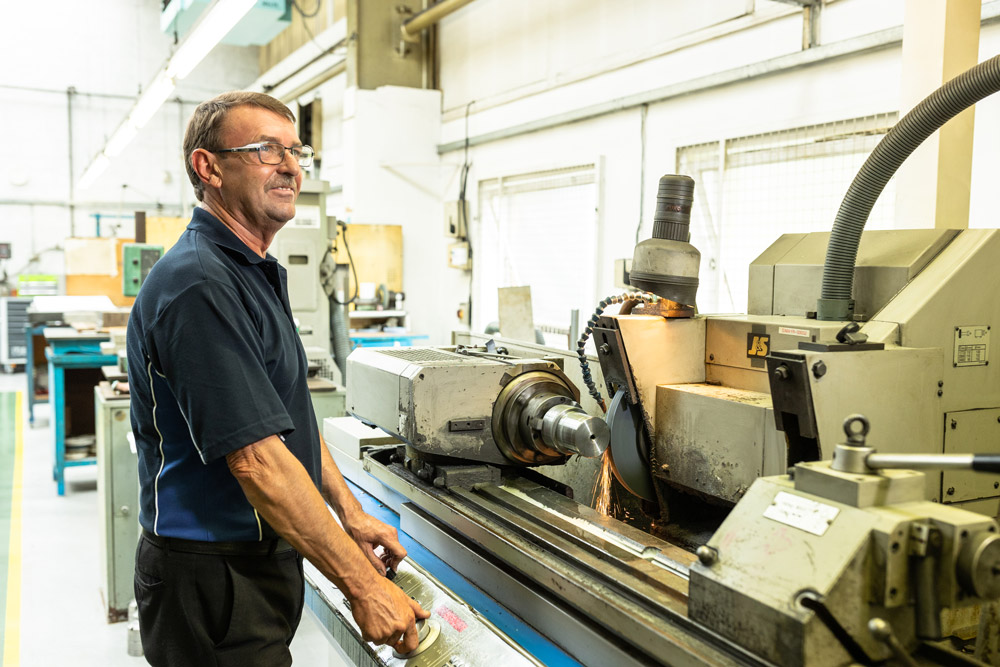

Grinding

Our comprehensive precision grinding facilities are essential for our toolmaking division, as well as our wider manufacturing operations. Accura has a range of grinding systems from leading manufacturers including Jones & Shipman.

| Grinding | Quantity onsite | Max X (mm) | Max Y (mm) | Max Z (mm) |

|---|---|---|---|---|

| Surface Grinders | 5 | |||

| Table Grinder | 1 | |||

| Wheel Grinder | 1 |

Laser Processing

Accura's 6-axis Trumpf Lasercell TLC 1005 is ideal for a wide range of laser processing operations, including cutting, etching and welding.

| Laser Processing | Quantity onsite | Max X (mm) | Max Y (mm) | Max Z (mm) |

|---|---|---|---|---|

| 6 Axis Laser | 1 | 3000 | 1500 | 600 |

Press Tooling

Press Tooling

Accura's power presses support our press tooling facility, allowing us to carry out tool try-outs and repair quickly and easily, while our smaller presses from leading manufacturers including Heim support the light fabrication division.

| Press Tooling | Quantity onsite | Max tonnage | Max X (mm) | Max Y (mm) | Max Z (mm) |

|---|---|---|---|---|---|

| Power Presses | 3 | 350 tonnes |

Engineering & Design

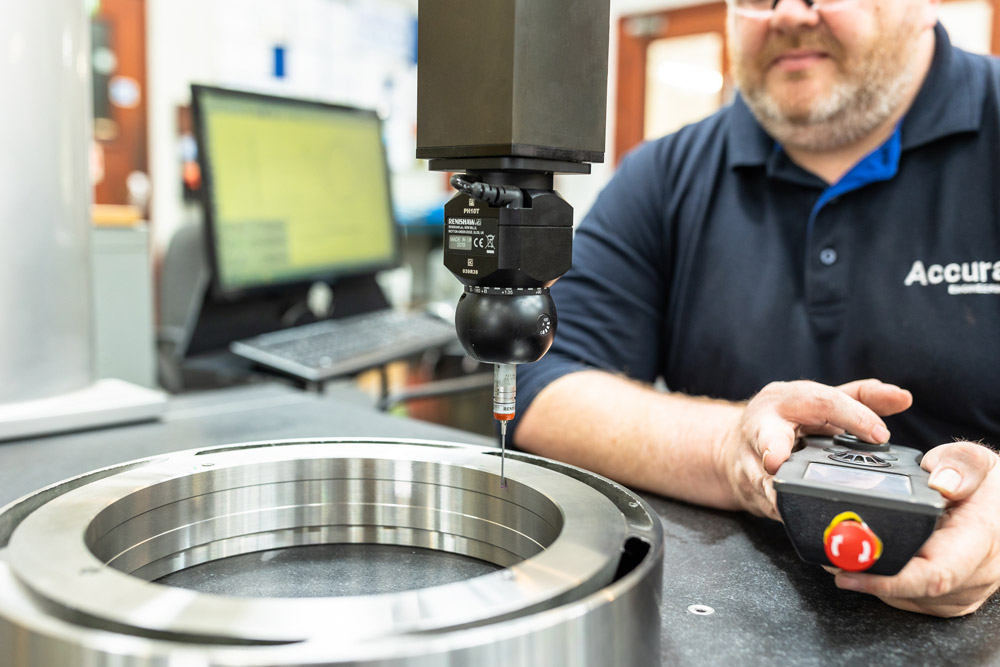

Inspection

Our fully-equipped inspection facility includes two CMMs to support our production activities, as well a wide range of manual inspection tools.

| Inspection | Quantity onsite | Max X (mm) | Max Y (mm) | Max Z (mm) |

|---|---|---|---|---|

| CMM | 2 |

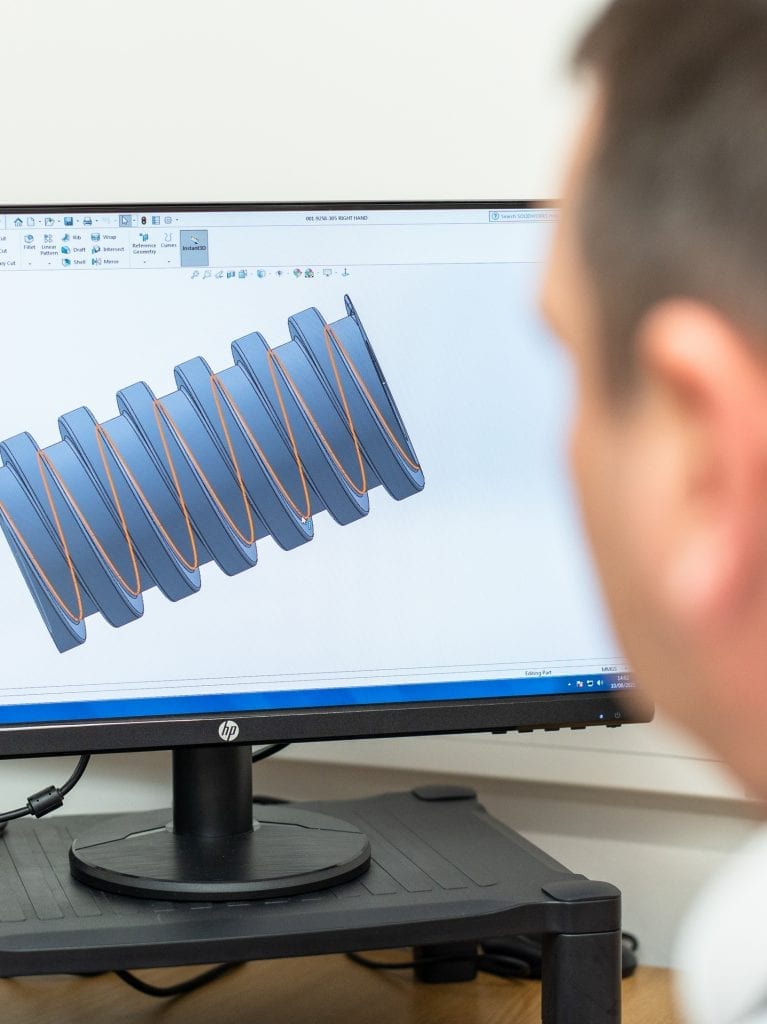

Engineering Software

Accura invests in the latest CAD/CAM software to ensure that we can support our customers' design activities and optimise our manufacturing process.

| Engineering Software |

|---|

| Solidworks |

| SolidCAM |

| PowerMill |

| RTM |

| ONECNC |

| Visi |